Polypropylene Valves For Power Plant

Power plant polypropylene valves are crucial fittings that withstand the power generation system’s rigorous operating conditions. Renowned for their phenomenal chemical resistivity, lightweightness, and durability, the valves serve well in applications demanding high performance when used with corrosive fluids and gases, whether in cooling water systems, chemical dosing, or wastewater management. Its high endurance impacts temperatures and environmental conditions, rendering it to be an economical and handy option for these engines. The installation is simple, and the amount of maintenance is bare as compared to its extended life, thus contributing to increased operational efficiency and safety in critical operations.

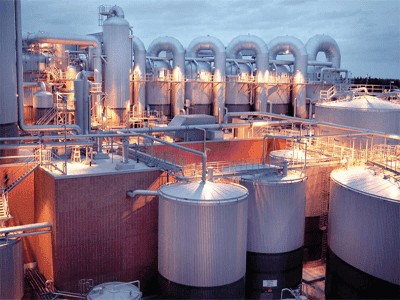

Polypropylene Valves For Chemical And Petroleum Industry

Polypropylene Valves in the Chemical and Petrochemical Industry are of paramount importance for application in aggressive chemicals, corrosive substances, and in hostile environmental conditions. These valves offer excellent resistance to an extraordinarily broad spectrum of acids, alkalis, and hydrocarbons, used in applications from chemical processing through storage and fluid transfer at refineries and petrochemical plants. Polypropylene valves are lightweight but constructed to withstand high temperatures and pressures, giving reliable and leak-proof operation. Add to this low maintenance, cost-efficiency, and performance even in the harshest environments, and it becomes clear that these valves are indispensable to making the chemical and petroleum industries absolutely safe and efficient.

Polypropylene Valves For Paper And Pulp Industries

Polypropylene Valves for Paper and Pulp Industries have become necessities concerning the usage of corrosive and abrasive fluid during pulp processing and paper production. They are known for their increased resistance against acids, alkalis, and other aggressive chemicals for dependable performance in harsh environments. Due to their very light and tough, they are easy to install and maintain. They are also able to tolerate very high temperatures and pressures, making them efficient in chemical dosing, wastewater management, and slurry handling. Cost-effective and long-life, polypropylene valves contribute to process optimization, less downtime, and maximum safety inside paper and pulp manufacturing plants.

Polypropylene Valves For Distilleries And Beverages Plants

Polypropylene Valves are used in Distilleries and Beverage Plants in managing fluids efficiently and hygienically. They can handle almost all chemicals and liquids used in production processes, being highly resistant to corrosion and light but durable. Such valves will serve in all applications such as water treatment, fermentation, and cleaning-in-place (CIP), as they perfectly comply with food-grade standards. Their smooth internal surface reduces contamination risks, ensuring that beverages are of the highest quality and safety. These valves are energy efficient, cost-effective, and need little maintenance while being reliable.

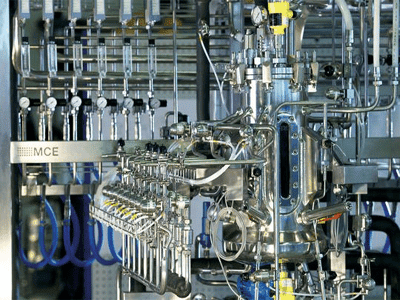

Polypropylene Valves For Pharmaceutical Plants

The valves composed of polypropylene are really essential components of pharmaceutical plants during vital processes to ensure the calculations, safety, and hygiene required in such core procedures. The excellent chemical resistance of these valves makes them suitable for any operation dealing with corrosives during the pharmaceutical production process. Lightweight and durable, these valves ensure that they are easy to install and perform for a long time under the most demanding conditions. They boast internal surfaces that are smooth and are compatible with cleanroom standards to minimize contamination risks that affect product integrity. Applications include a wide variety of things, from water purification systems to chemical dosing and fluid transfer. Polypropylene valves are the most widely used valves in plants of pharmaceuticals owing to their reliability and meeting the requirements of stringent regulations.

Polypropylene Valves For Effluent Treatment Plants

These valves help in the effective controlling of wastewater and treated effluents through an effluent treatment plant. These valves stand for their high and unparalleled chemical resistance and are thus driven to transfer solvents, acids, alkali, sludges, and other domestic and industrial effluents, and corrosive, abrasive products from treatment processes. Being lightweight yet durable makes these valves easy to install and capable of withstanding extreme temperature conditions. However, polypropylene valves are used in virtually all chemical dosing, flow controlling, and discharge systems. These valves with good sealing and low maintenance will help in the process optimization and in better efficiencies following environmental regulations and sustainable wastewater treatment.

Polypropylene Valves For Varnish Industries

These valves are used specifically for the varnish industries and are meant to grapple with problems such as transferring and mixing corrosive chemicals and solvents. Polypropylene valves provide excellent resistance to a variety of chemicals while ensuring durability and leak-proof functionality in demanding environments. They are easy to install and robust to handle high temperatures and pressures. These valves help achieve an efficient and safe varnish-making process. Very low maintenance requirements with an extremely long service life make it an economical solution for varnish industries to provide smooth processes.

Polypropylene Valves For Oil Industries

Polypropylene Valves for Oil Industries offer maintainable qualities for all the oil exploring drilling, refining, and distribution industry needs. They are resistant to corrosive media, hydrocarbons, as well as to the most hostile chemicals and are thus suited to control and transfer liquids in very demanding environments. They are lightweight construction material and strong enough to resist the rigors of installation site for critical applications chemical dosing, wastewater management, and pipeline system applications. Polypropylene valves have found their acids high in pressure performance, applicable for high temperatures and have therefore minimized the risk of leakage failure. Economical and requiring low maintenance, they are the best options for making a place in the oil industry’s operational process.

Polypropylene Valves For Cement Factories

Polypropylene valves for cement plants are essential in handling the most rigors and radical processes of cement-making. In terms of slurry handling, water management, and chemical dosing applications, these valves offer great resistance to abrasive materials, corrosive chemicals, and extreme operating conditions. Their lightweight construction makes them easy to install, while durability ensures high pressure and temperature resistance. Polypropylene valves guarantee excellent and low-maintenance performance in even the harshest environments, ensuring processes continue running without interruption. Economical and efficient, they optimize operations, save downtime, and improve overall productivity in cement-making plants.

Polypropylene Valves For Gas And Solvents

Polypropylene Valves for Gas and Solvents arn the valves made for the safe and efficient distribution of gases and solvents in industrial applications. These valves show excellent corrosive and volatiles resistance to chemicals; hence, they are expected to work for quite some time in environments where other standard materials would have perished. They are lightweight and handy for installation but can withstand quite high pressures and temperatures, which usually find their way into gas and solvents systems. Furthermore, they possess the smooth internal surfaces that minimize any contaminating and clogging incidences made most applicable in the chemical processing, storage, and distribution systems for safety, efficiency, and reliability in handling these gases and solvents.