The Different type Of Polypropylene Valve Range in Ahmedabad

Polypropylene valves are commonly utilized in many industrial and chemical fields on account of their high chemical resistance, lightweightnature and low costs. These valves are manufactured in polypropylene thermoplastic polymer, and the features possessed by valves are excellent durability and lifelong performance due to the corrosive environment surrounding them where metal valves might corrode or show malfunctions. They also find utility in working with acidic solutions, corrosive alkalis and other chemicals that are aggressive and thus make them a better option, especially in the chemical and water treatment industries, the pharmaceutical industry, and agriculture.

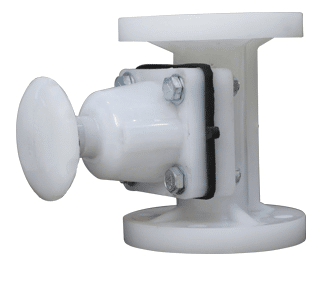

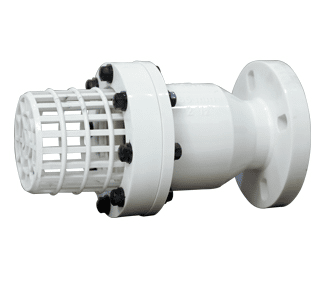

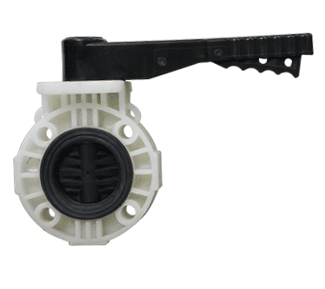

Among the greatest strengths of polypropylene valves is the resistance to a wide variety of chemicals in such a way as it does not impair the flow control and structural integrity of the valves. They are not toxic and hence can be used in applications that require the usage of potable water and food-grade systems. There are numerous types of these valves, such as ball valves, diaphragm valves, check valves, and butterfly valves, and each of them is designed to be used in the conditions that imply particular flows and pressures. They can also be easily installed and do not put high loads in the piping system, which in turn keeps the overall cost of operation down due to their lightweight nature.

In addition, polypropylene valves are maintenance-free and have an excellent mechanical performance even when used in higher temperatures. They cannot rust, corrode or accumulate scales, which makes them have a stable and dependable performance. They are made so that their interior is smooth, and they minimize friction loss in addition to increasing flow efficiency. Owing to these attributes, polypropylene valves also possess the benefit of being a cost-effective substitute for conventional metal valves, particularly in sorts of usage whereby chemical resistance is of the utmost importance.

In short, polypropylene valves strike a balance of strength, resistance to chemicals and low costs and, as such, provide a solution to the industry for a large variety of applications. The performance is as well as the value provided by their capability to fit into various environments and low maintenance requirements. Be it aggressive chemicals where the valves are supposed to carry and release them safely or when it comes to the flow of clean water, polypropylene valves remain one of the most viable and reliable alternatives.