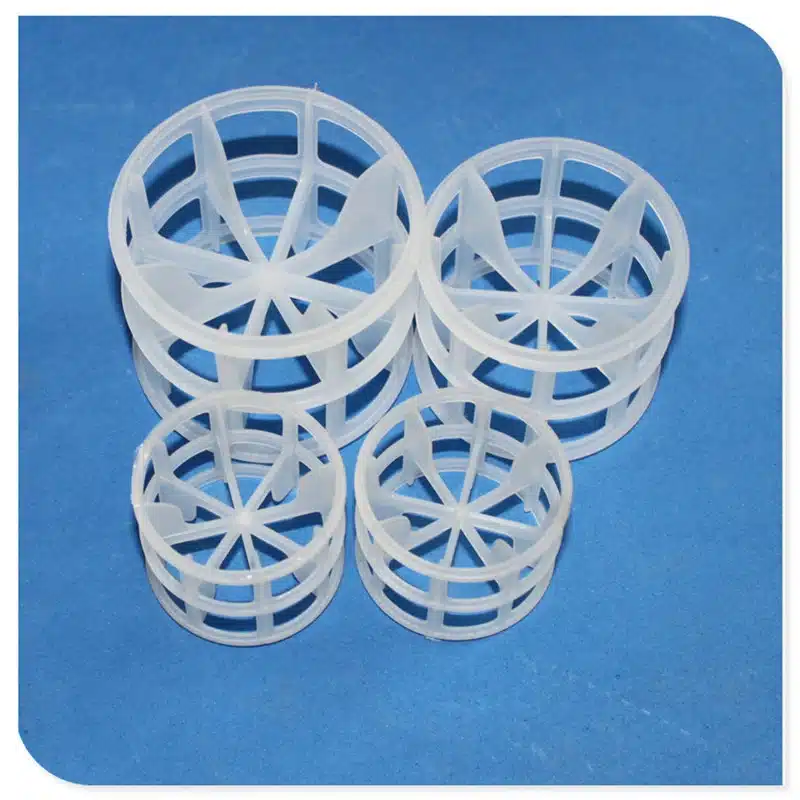

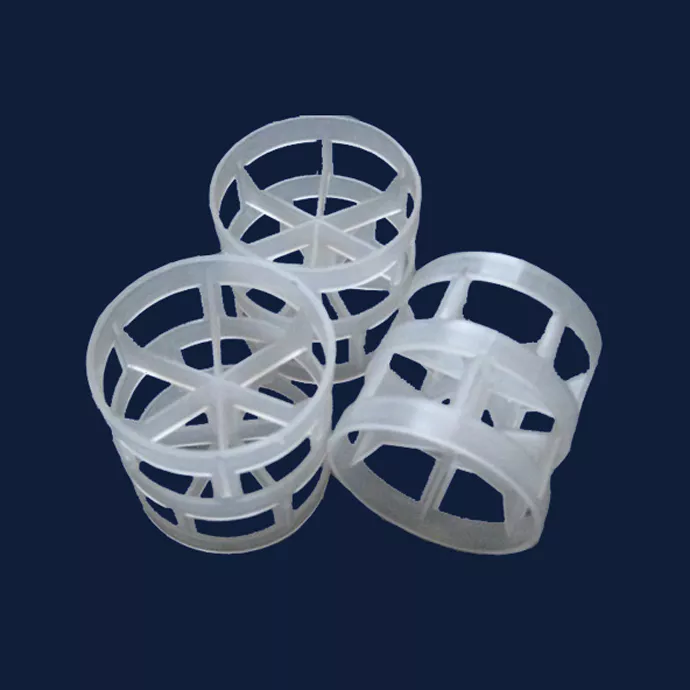

Polypropylene Plastic Pall Ring Manufacturer, Supplier & Exporter

The majority of thermoplastics are made from polypropylene grades in various forms. Additionally, high- performance plastics are used for producing polypropylene. Regenerates are based only on a special request. Polypropylene Plastic Pall Ring is the single piece molded with polypropylene, and these most efficient types of ring packaging for large scale distribution has superior characteristic that derive from the slotted wall and the internal projecting tongues, which gives this higher capacity and lower pressure drop. It also has high efficiency that arises from the better disposition and better wetting of the surface, and the migration of the liquid forward to the vessel wall is also reduced.

Polypropylene Plastic Pall Ring is also known as PP pall ring, and it is widely used as separator in gas and liquid applications. It has outstanding chemical resistance, temperature stability, and mechanical strength. The structure of plastic pall ring is a somewhat different from the ceramic pall ring and metallic pall ring. For both of these rings, there are two layers of windows on the cylinder wall and ligules bending inward the axes of the ring on the cylinder wall. There are two layers of window on the plastic cylinder wall, and the fingers on the wall bend inward from the ring and form different shapes.

Size | NOS./CU.M. | SURFACE M2/M3 | VOIDAGE | PACKING FACTOR F |

17mm | 2,11,000 | 335 | 85 | 94 |

18mm | 99,000 | 234 | 85 | 67 |

24mm | 50,000 | 200 | 85 | 52 |

37mm | 13,000 | 130 | 90 | 30 |

49mm | 6,000 | 100 | 88 | 20 |

74mm | 1,700 | 90 | 89 | 19 |

90mm | 1,000 | 80 | 88 | 15 |